Produce your own iconic packaging on your site, on demand, directly from a roll

From Roll to Bottle, the solution patented by UBLO

Thanks to Ublo technology, you can produce your packaging directly from plastic sheeting in roll

. The Ublo solution allows you to produce very

lightweight and highly competitive packaging, on demand, in line with the filling process. Our machines can produce up to 30,000 packagings per h

our without injection or extrusion or melted plastic processing .

How to simplify your process with Ublo

Benefits for manufacters

On the transport:

- Stop transporting empty packaging

- Reduce both your packaging cost and your CO2 emissions

On the logistic:

- No more storage of empty packaging

- Reduce bottle handling on the line

- Reduce contamination risks

- Increase hygienic standards

- Simplify your supply chain

Cost reduction

- Buy rolls of plastic sheet instead of empty bottles and save on packaging

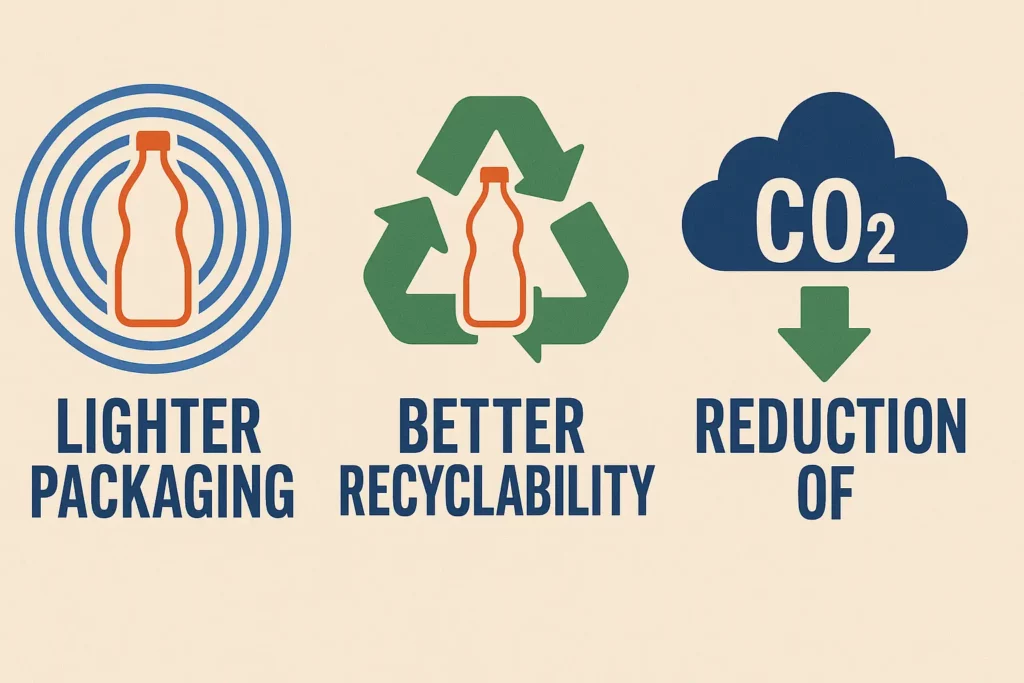

- Reduce packaging weight

Reduce

- Carbon footprint

- Energy consumption

- Packaging weight

Wide range of containers

Materials

- PP, PE, PLA, …

Multilayer structure

- Oxygen barrier (EVOH, or others)

- Light barrier

Thermal resistance

- Retort resistance (PP)

- Hot filling (PP)

- Suits for microwave heating (PP)

- Suits for aseptic decontamination

From idea to bottle...

We collaborate closely with our clients through iterative prototyping and testing.

This agile approach ensures that the packaging not only meets functional and marketing goals, but also maximizes efficiency and sustainability.